Intertenancy Walls

Logicwall intertenancy wall system for medium-density projects.

AFS Logicwall® panels are used as load bearing intertenancy walls to to help Architects, Builders, and Engineers simplify medium-density design.

Benefits

Maximise Floor Space

Maximise Floor Space

Logicwall® intertenancy walls can help maxmise space while assuring all standards are meet.

With wall thicknesses as thin as 162mm, we can help you create more space in your medium density housing.

Logicwall intertenancy walls can help maxmise space while assuring all standards are meet.

With wall thicknesses as thin as 162mm, we can help you create more space in your medium density housing.

Acoustic Performance

Acoustic Performance

Intertenancy wall options range from 55-69 STC acoustic rating.

Intertenancy wall options range from 55-69 STC acoustic rating.

Fire Performance

Fire Performance

Logicwall® intertenancy walls can achieve a fire rating of 240/240/240.

Logicwall intertenancy walls can achieve a fire rating of 240/240/240.

Load Bearing Structure

Load Bearing Structure

Once walls are core filled with concrete they act as a load path for the Engineer helping to simplify structural design.

Once walls are core filled with concrete they act as a load path for the Engineer helping to simplify structural design.

Logicwall is becoming the preferred choice for Architects, Builders, and Engineers for intertenancy walls.

Logicwall is becoming the preferred choice for Architects, Builders, and Engineers for intertenancy walls.

Intertenancy Wall Options

.

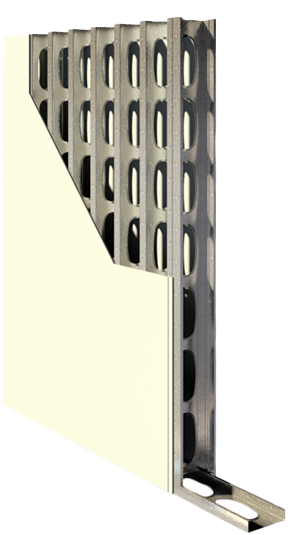

LW150

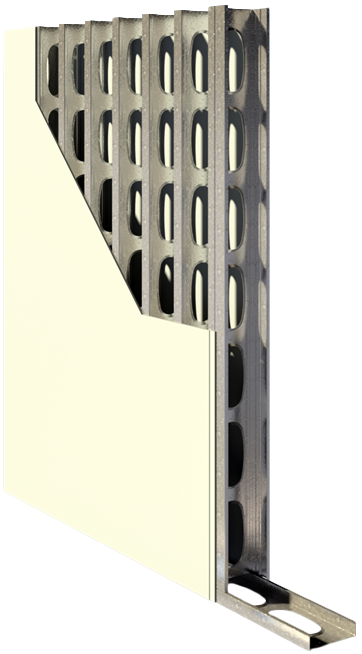

LW162

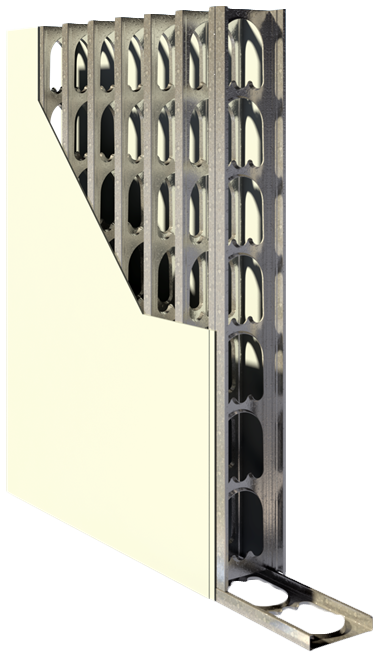

LW200

Thickness

150mm

162mm

200mm

Fire Resistance Level (FRL)

240/240/180

240/240/240

240/240/240

Acoustic Rating (STC)

54

55

58

Strapping and Lining one side

Acoustic Rating (STC)

61

62

64

Thickness

204mm

216mm

254mm

Strapping and Lining two sides

Acoustic Rating (STC)

67

68

69

Thickness

276mm

288mm

329mm

Refer to AFS acoustic report for further options or reach out to us.

Logicwall Installation

Start designing your intertenancy walls in Logicwall today

Send us your plans and we’ll provide you with a proposal for your project.

Start designing your intertenancy walls in Logicwall today

Send us your plans and we’ll provide you with a proposal for your project.

Everything you’ll need to know to get started with using AFS Logicwall for intertenancy walls.

FAQs

What is AFS Logicwall®?

AFS Logicwall® is a permanent formwork system for concrete walling applicable for external and internal applications. It consists of lightweight sandwich panels created by bonding hard-wearing fibre cement sheets to galvanised steel stud frames.

What is the main applications for AFS Logicwall®?

- Intertenancy walls

- Corridor walls

- Lift and stair walls

- Boundary walls

- Exterior walls

- Façade walls

- Blade walls

- Balustrades

How is AFS Logicwall® installed?

-

Panel Installation

AFS Logicwall® is renowned for its speed of construction and its ability to deliver large structures in record time

Step 01– Floor track

Floor track is fixed to the marked out slab over reinforcement starter bars.

Step 02– Easy lift

Panels are erected by hand – teams of three men per panel, using a set technique.

Step 03– Alignment

Panel joiner stud is aligned with the standing panel.

Step 04– Install

Standing panel is lowered down over the reinforcement starter bars.

Step 05– Secure

Panel is locked into place over the floor track.

Step 06– Bracing

Walls are temporarily braced at panel joints with purpose-built adjustable braces.

Step 07– Reinforcement

Vertical and horizontal reinforcement bars are placed in walls to project engineer’s specification.

Step 08– Wall straightening

Panels are plumbed and straightened with levels and string lines.

Step 09– Electrics

Electrical conduits are installed from the top of the panel.

Step 10– Plumbing

Conduits and pipes for plumbing services are generally attached to the wall which is strapped and lined.

Step 11– Core filling

After the installation process is complete the panels are then core filled with concrete using concrete pumping methods, generally using a boom pump.

What are the lead times for AFS Logicwall®?

Typical lead times for AFS Logicwall® is 8-10 weeks. This includes our shop drawing process timeframe.

What are the main benefits using AFS Logicwall® as intertenancy walls?

- Our 162mm profile is the thinnest compliant intertenancy wall on the market

- Speed of construction

- Materials handling and resulting cost efficiencies

- Panels are custom made for each project reducing on-site waste

- System is load bearing

- Offers a consistent high quality finish

- Offers ease of design and specification

How are AFS Logicwall® internal walls finished?

For internal wall finishing, AFS Logicwall® can be:

- Joint set and skim coated

- Lined with plasterboard.

Contact us to discuss your projects required level of finish.

I'm already designing in another system, what is involved in changing to AFS Logicwall?

We’ve helped many projects convert to AFS Logicwall. Contact us today to discuss your project.