A prefab solution to blockwork that saves time, cost and waste

A prefab solution to blockwork that saves time, cost and waste

With rising costs and materials not available as readily as they used to be, professionals in the construction industry are constantly searching for innovative ways to ensure a project’s success.

With the goal of providing solutions for architects, developers, builders and engineers to work smarter, not harder, AFS Wall has been supplying prefabricated PVC Rediwall to the New Zealand construction industry – and it’s proven to be a valuable product.

How does Rediwall compare to blockwork?

It’s a very lightweight system and the panels can help reduce the thickness of the wall overall. It’s also at least twice as fast to install than blockwork in most applications.There’s also less waste created on site when using Rediwall – you haven’t got masonry concrete blocks being cut down to size, there are no piles of sand and cement required for the mortar being left on site. It’s creating less waste and taking up less space on site.There’s also less waste created on site when using Rediwall.

What applications can it be used for?

It is useful for house foundations, garage and basement structures, retaining walls, swimming pools, retention tanks, and high-end residential homes that would typically use blockwork.

What are the benefits of using Rediwall?

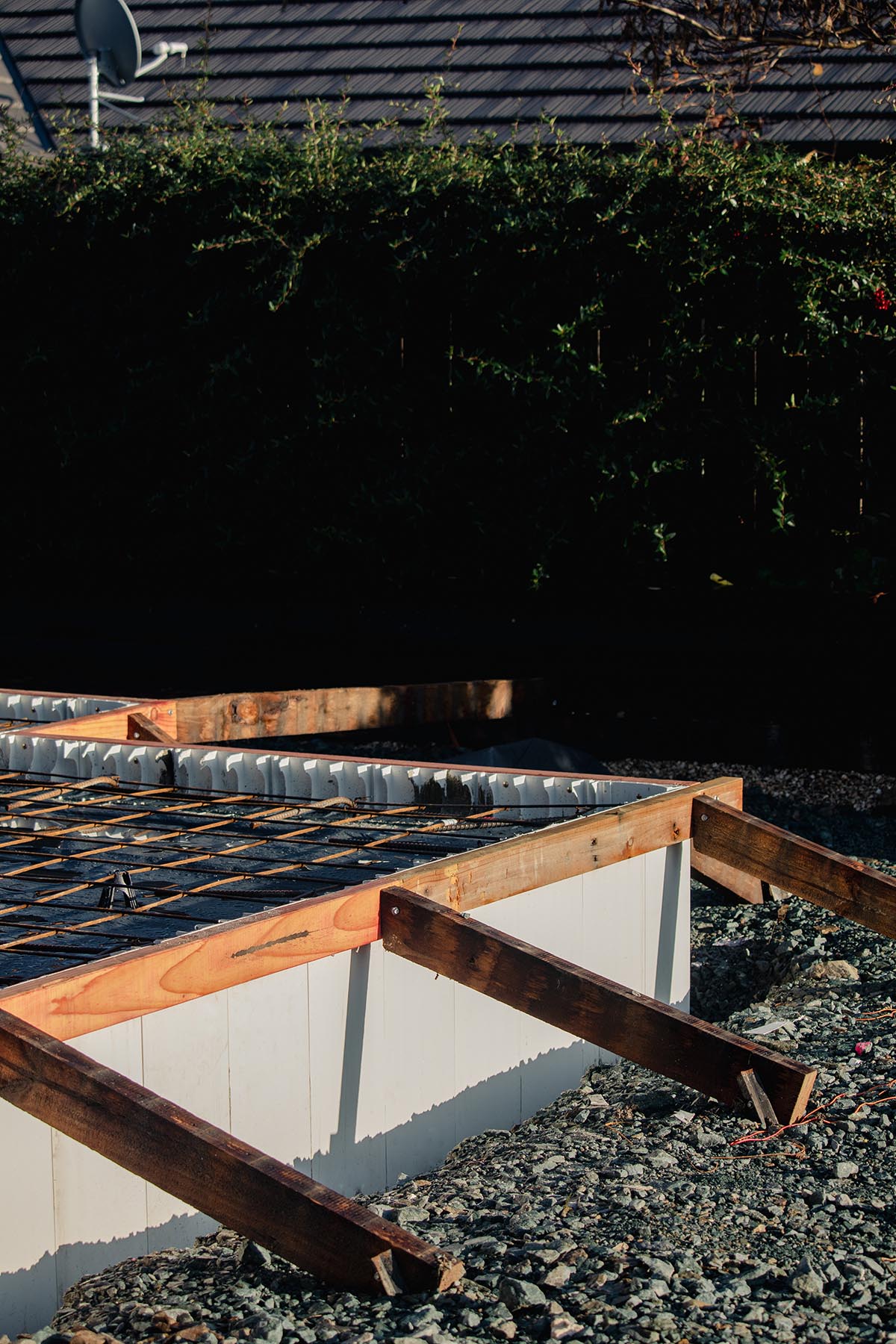

On a recent project – a 600mm high foundation wall – the builder, rather than having to wait for a blocklayer to come and install concrete blocks before continuing with the rest of the built – utilised their own labour on site to install all of the Rediwall, and poured it themselves. He said that they ended up with a better quality finish to the foundation than what it would normally have.This was the first time for the builder using Rediwall, and they’ve already contacted us about swapping their next project from blockwork to Rediwall because it saved them time and money.

What does the installation of Rediwall look like?

Installation guides are available and we also provide installation and training support. With larger projects such as multi-residential and large commercial projects, we actually provide a full supply and installation solution with our own installers.The panels are lightweight and click together. They are then braced, reinforcing is installed, and then it’s filled with concrete.We offer a lot of support to architects, engineers and builders. We’ve got an in-house team with construction experience that can support and advise on projects.The panels are lightweight and click together. They are then braced, reinforcing is installed, and then it’s filled with concrete.

What finishing options are available?