Basement Walls

Rediwall Basement Walls

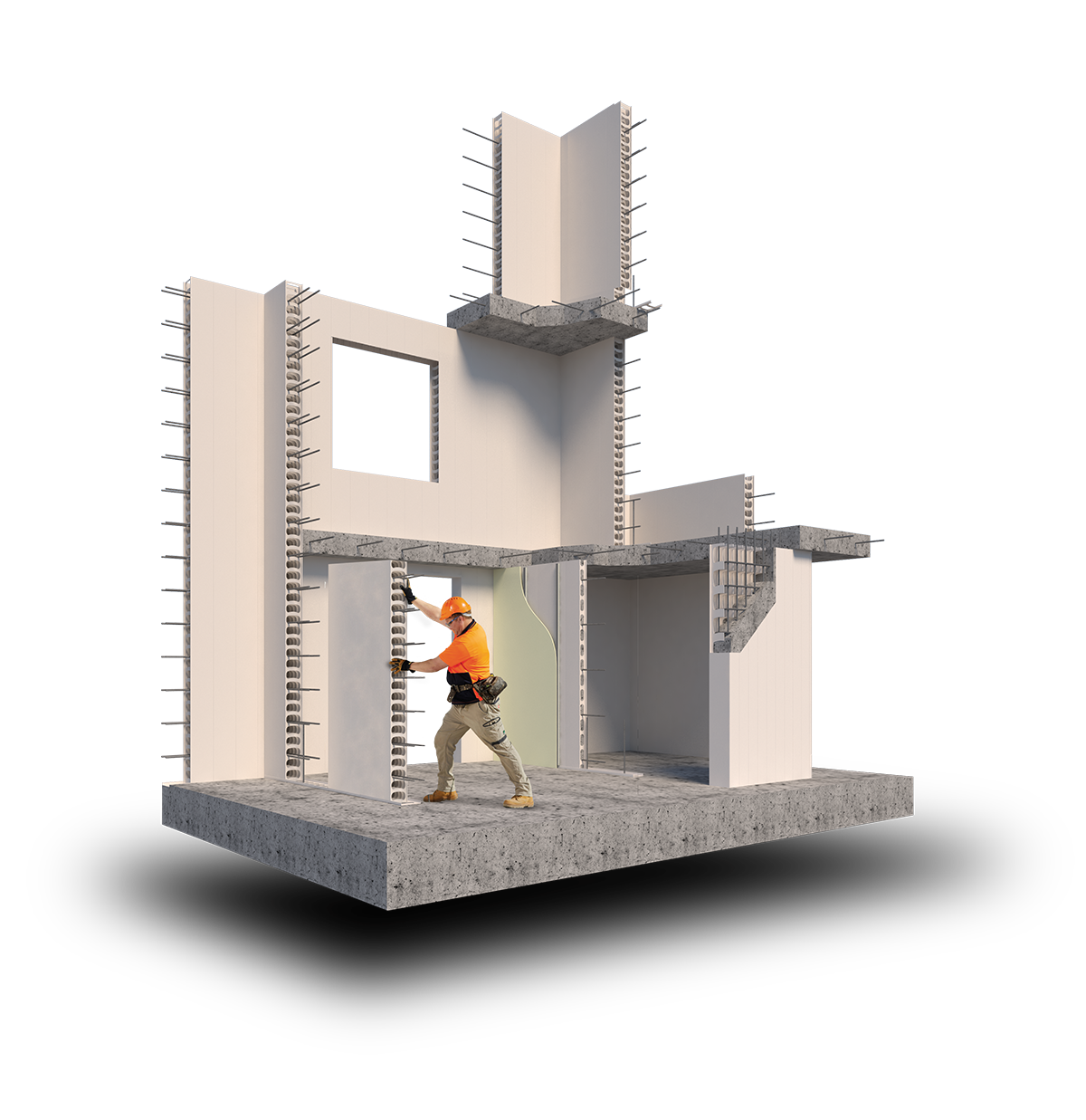

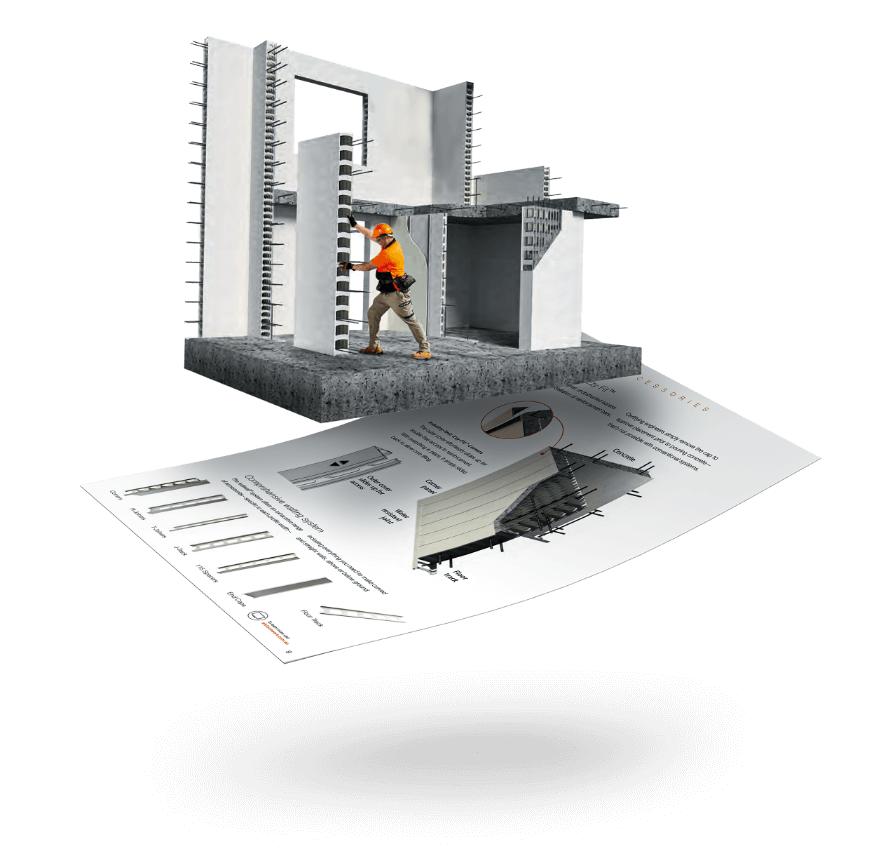

AFS Rediwall offers a smart, cost-effective solution for basement wall construction in residential and multi-residential projects. The system is designed to simplify the build process, speeding up installation while helping to keep projects on time and within budget.

Whether it is multi-residential developments, high-end homes, or underground car parks, Rediwall delivers durable and high-quality basement wall solutions. As a versatile permanent formwork system, it ensures strength, efficiency, and a clean finish for all basement wall applications.

Benefits

Benefits

Speed of Construction

Rediwall can cut your installation times in half compared to traditional masonry methods.

Easy to Design

Simplified design, making Rediwall basement walls easy to plan and integrate into any project.

Builders Can Install It

Builders can easily install the Rediwall without relying on other trades, while the AFS team is available if required.

Load-Bearing

Rediwall can be a load-bearing basement wall, suitable for small and large developments.

A cost-effective and faster to install option for basement walls

A cost-effective and faster to install option for basement walls

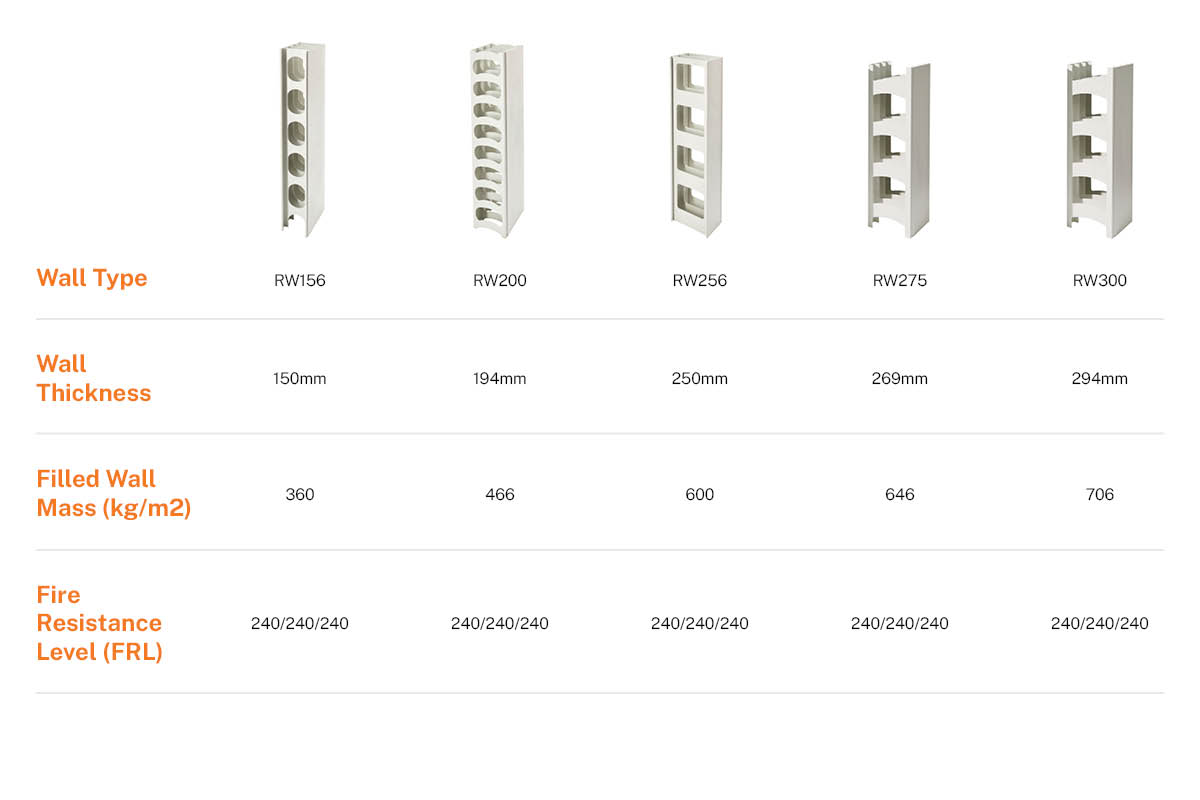

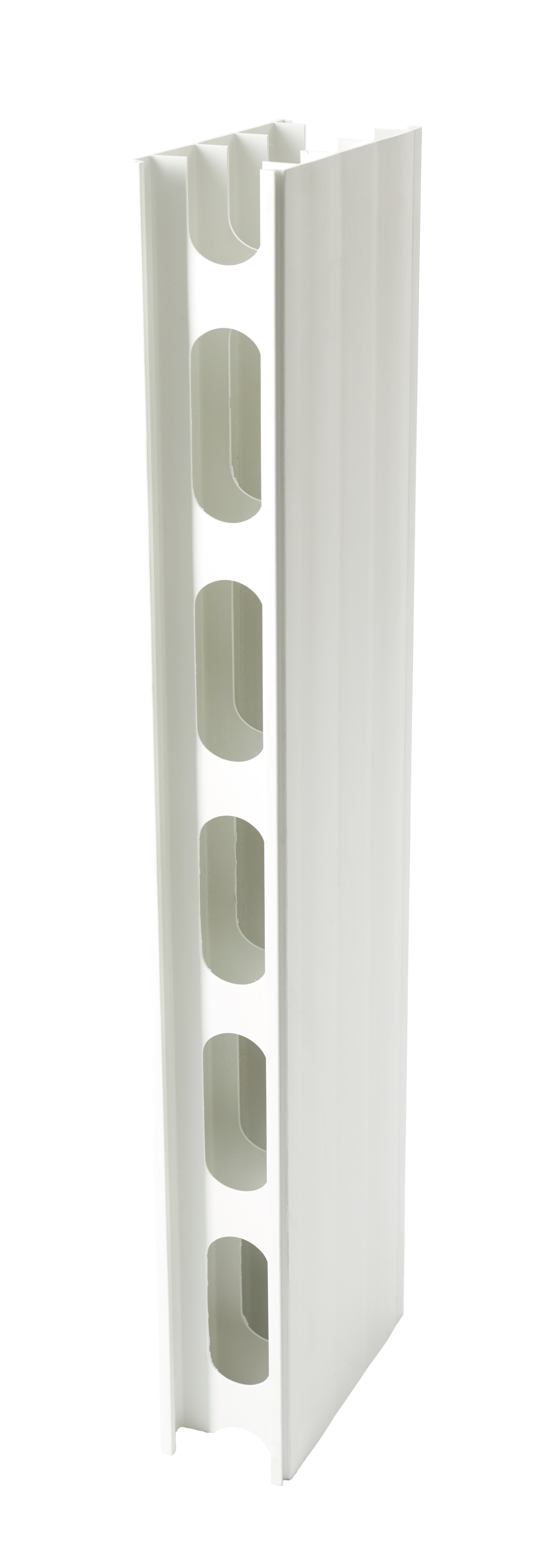

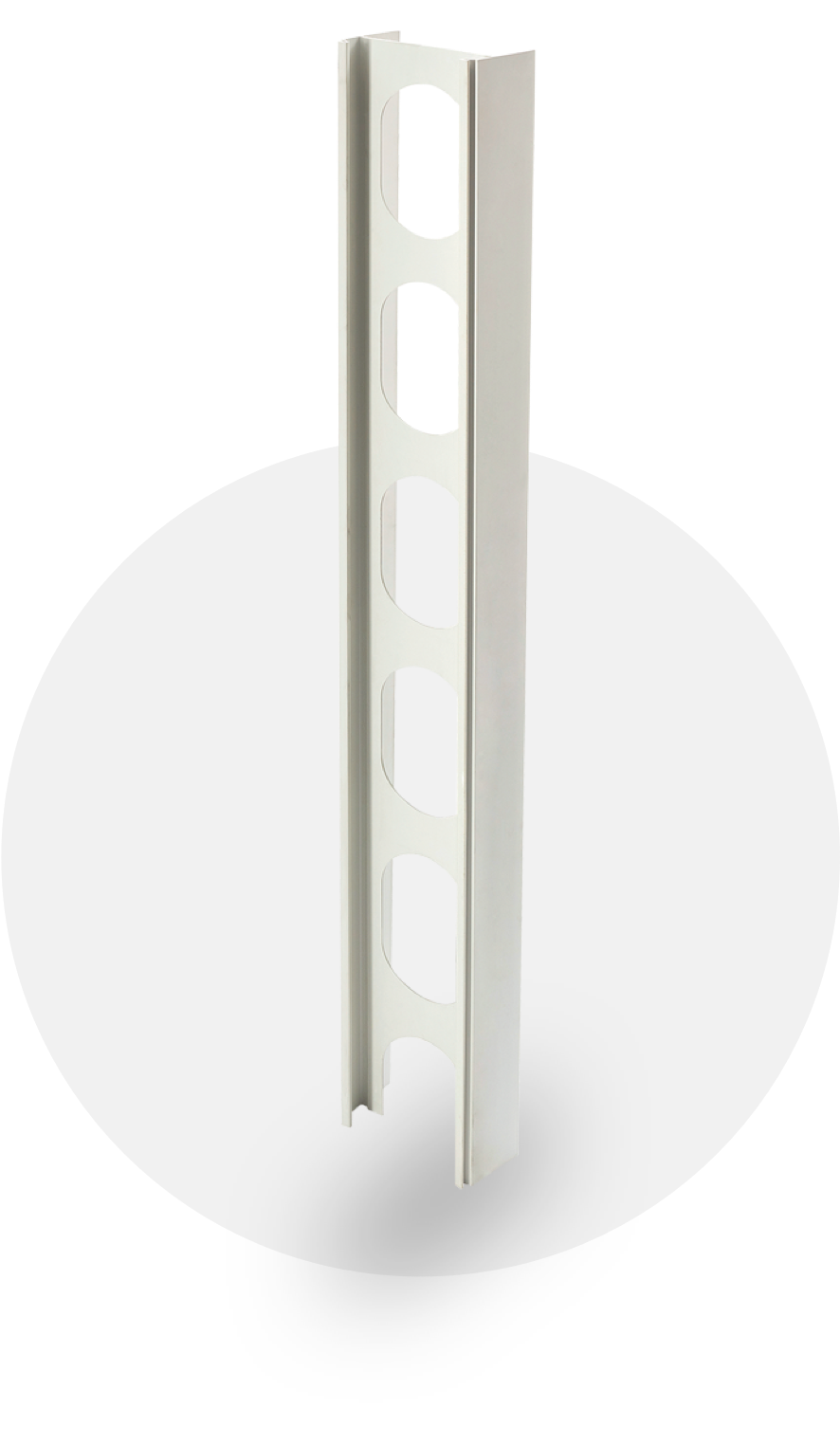

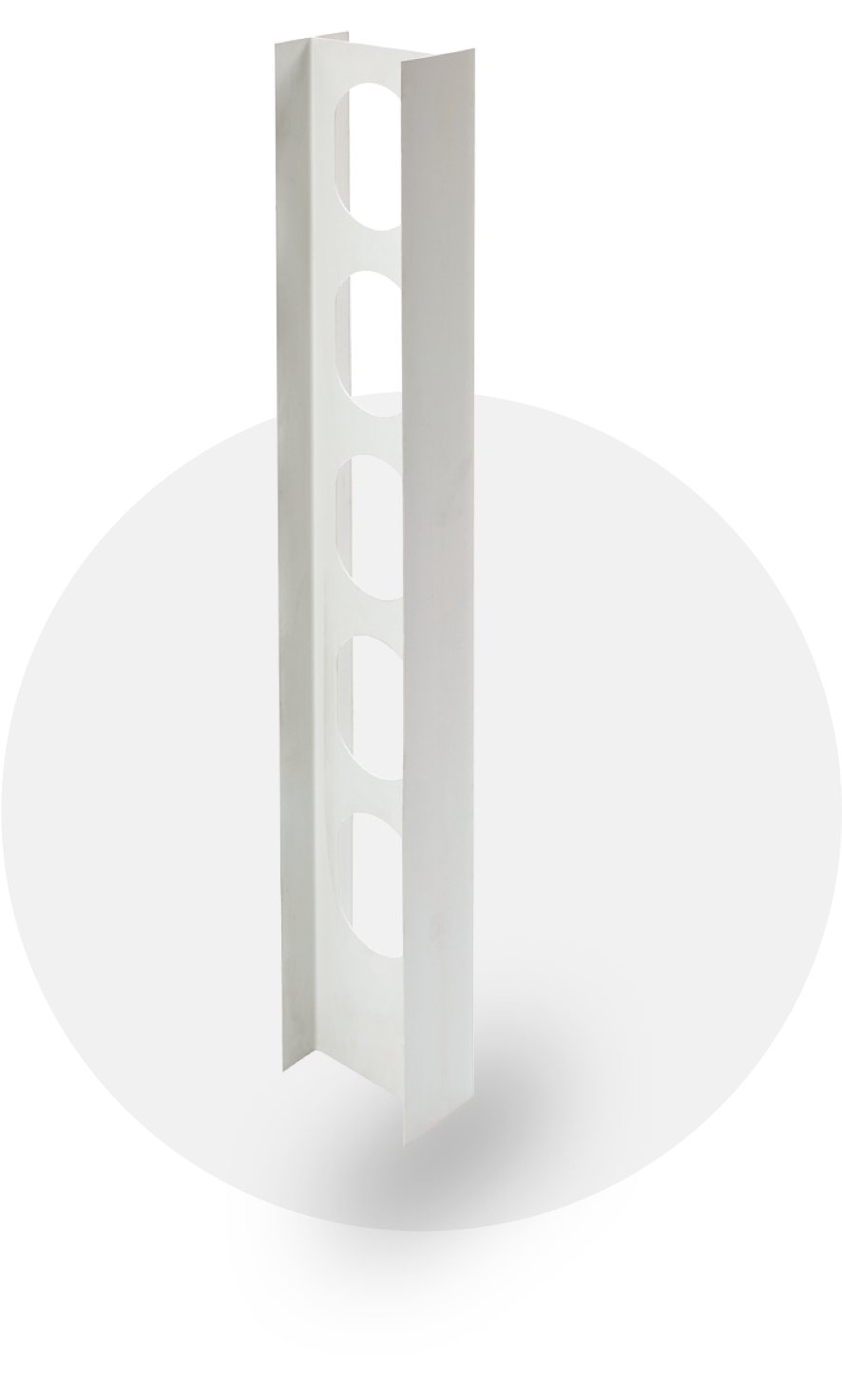

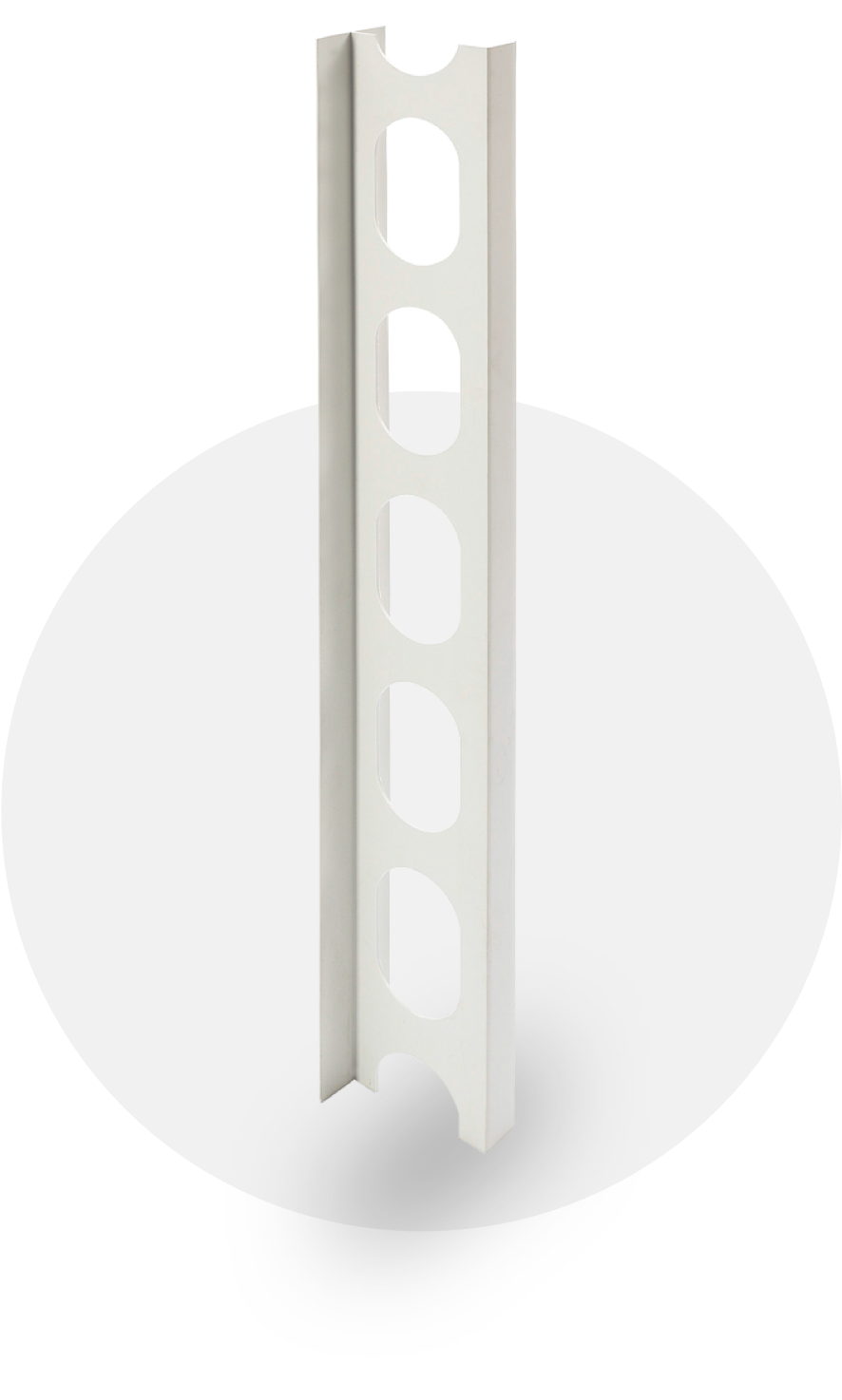

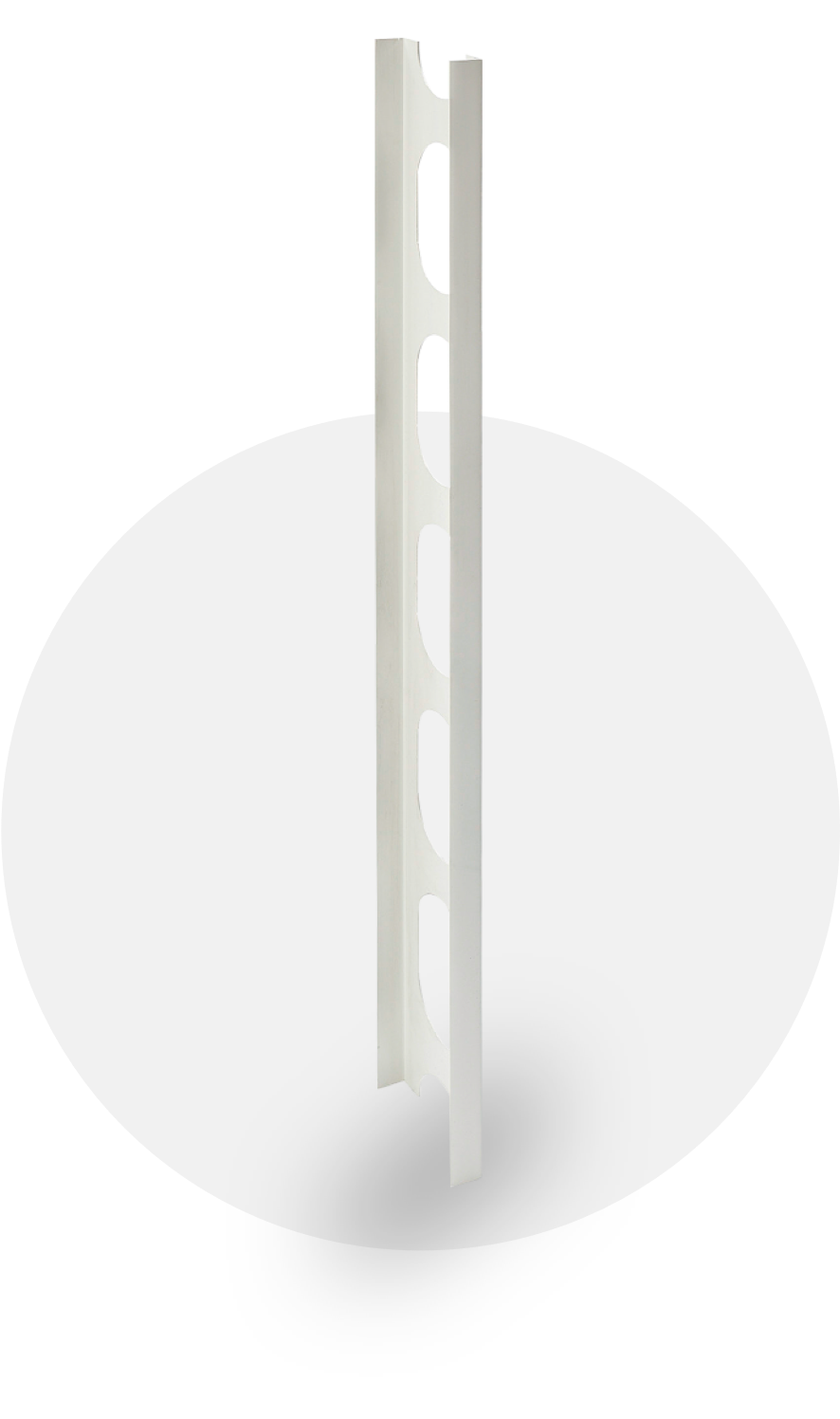

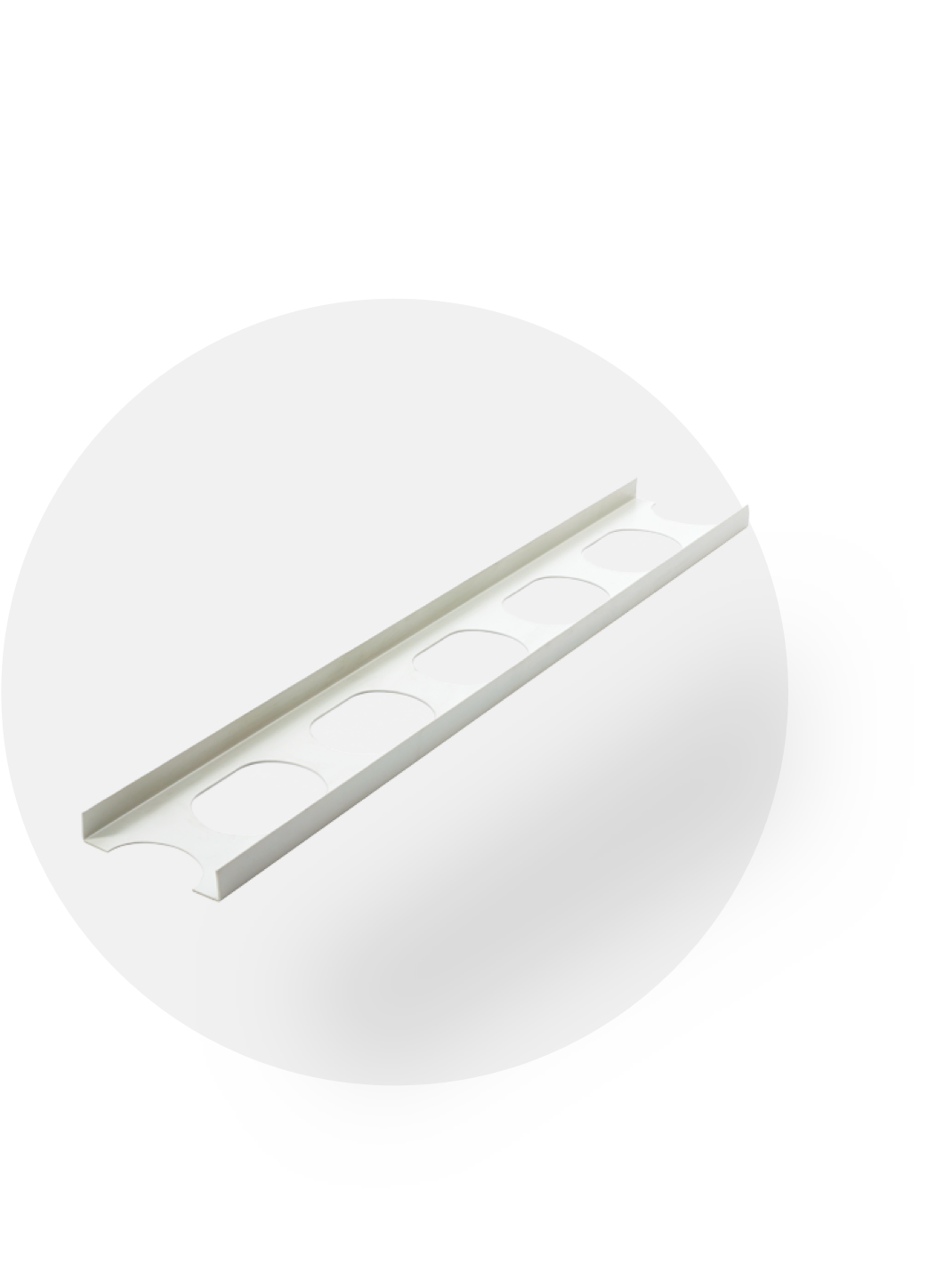

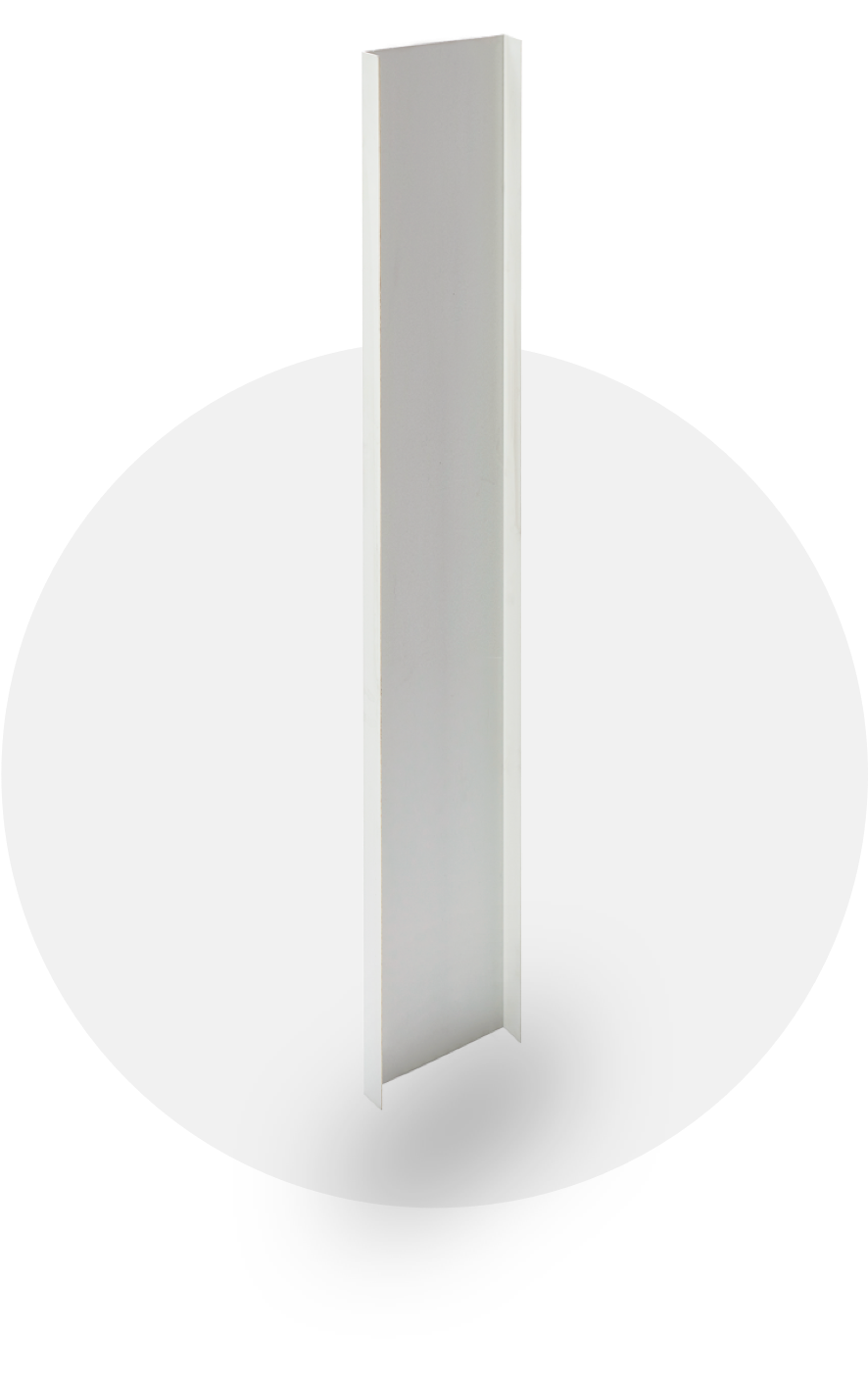

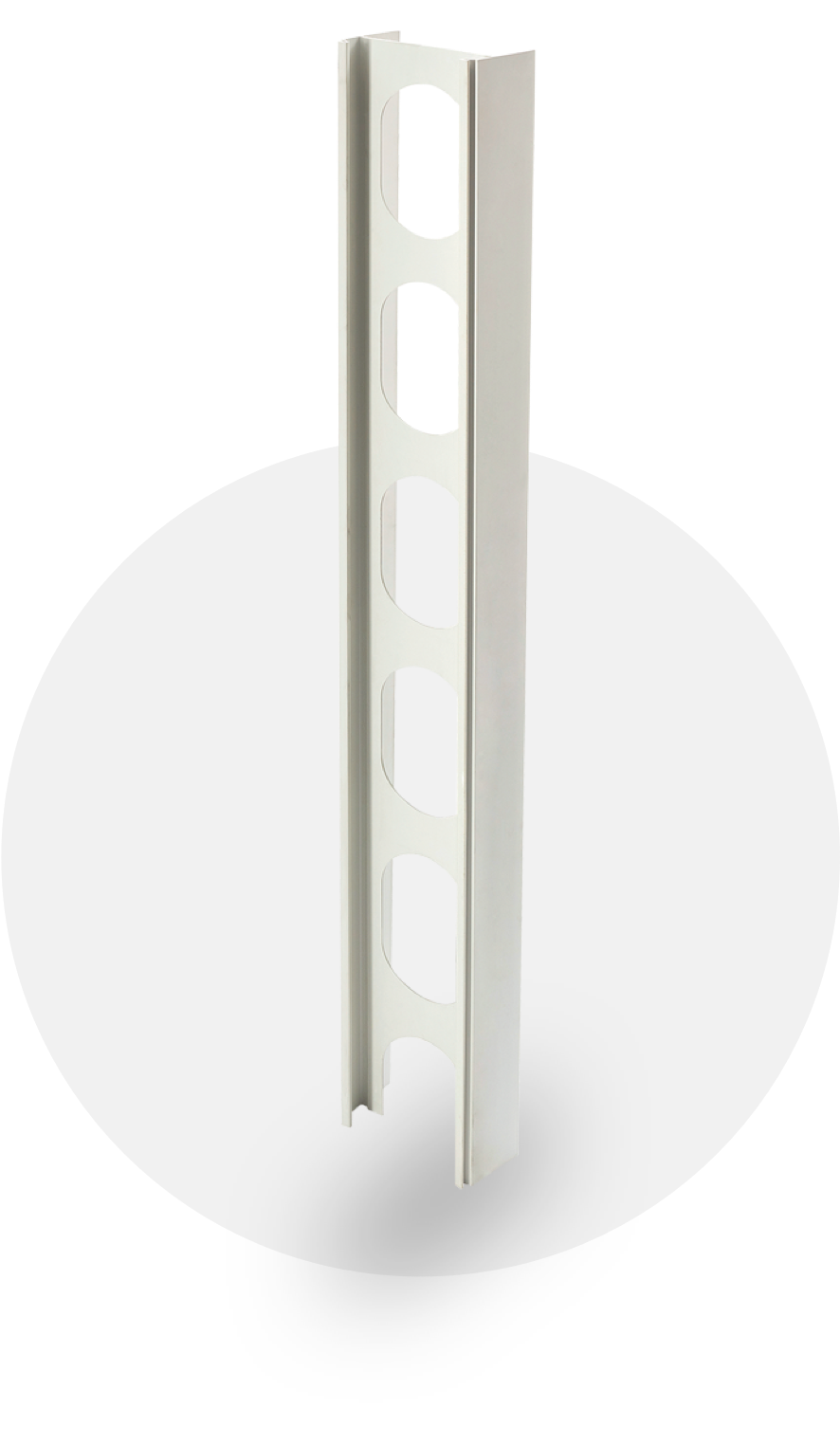

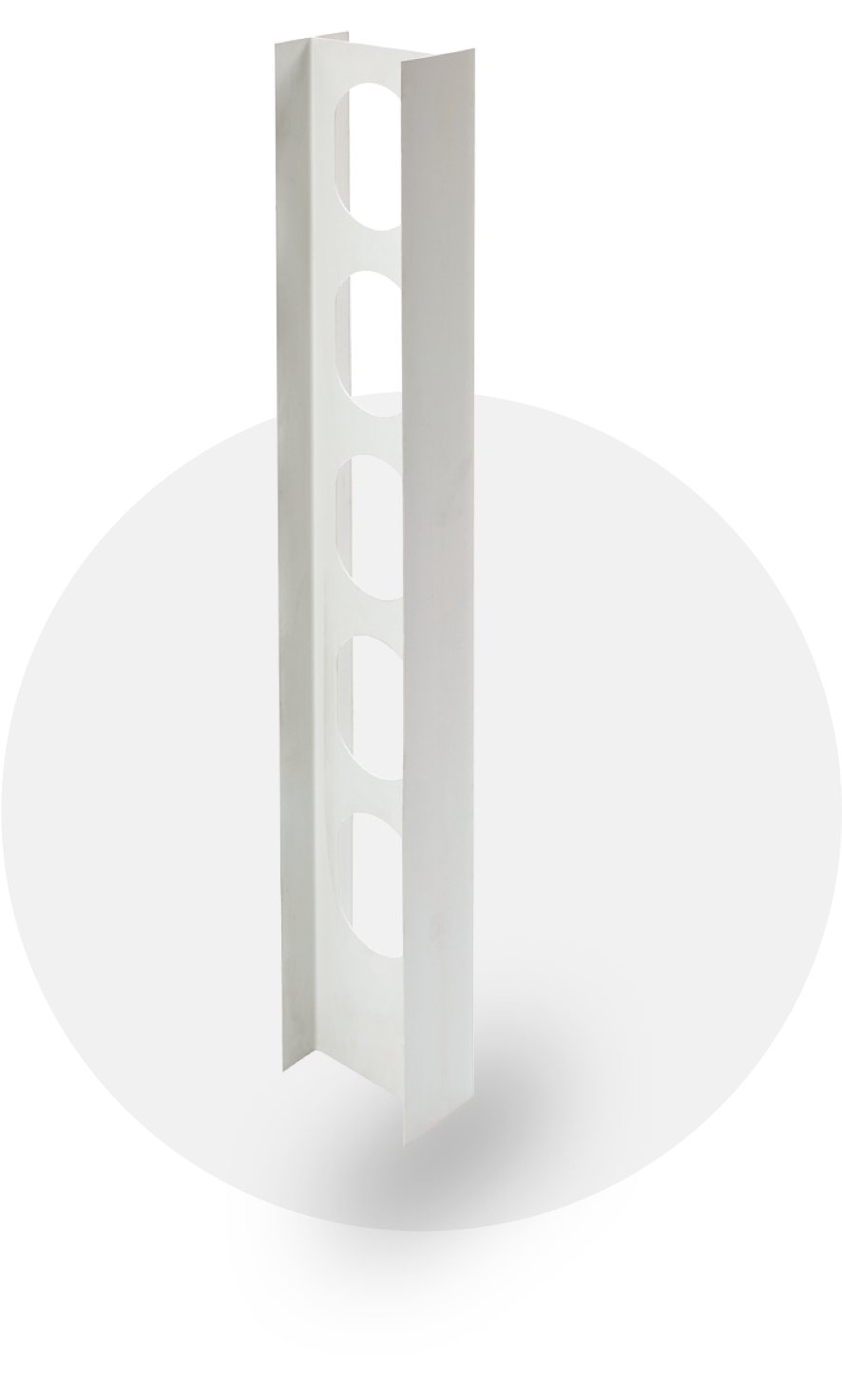

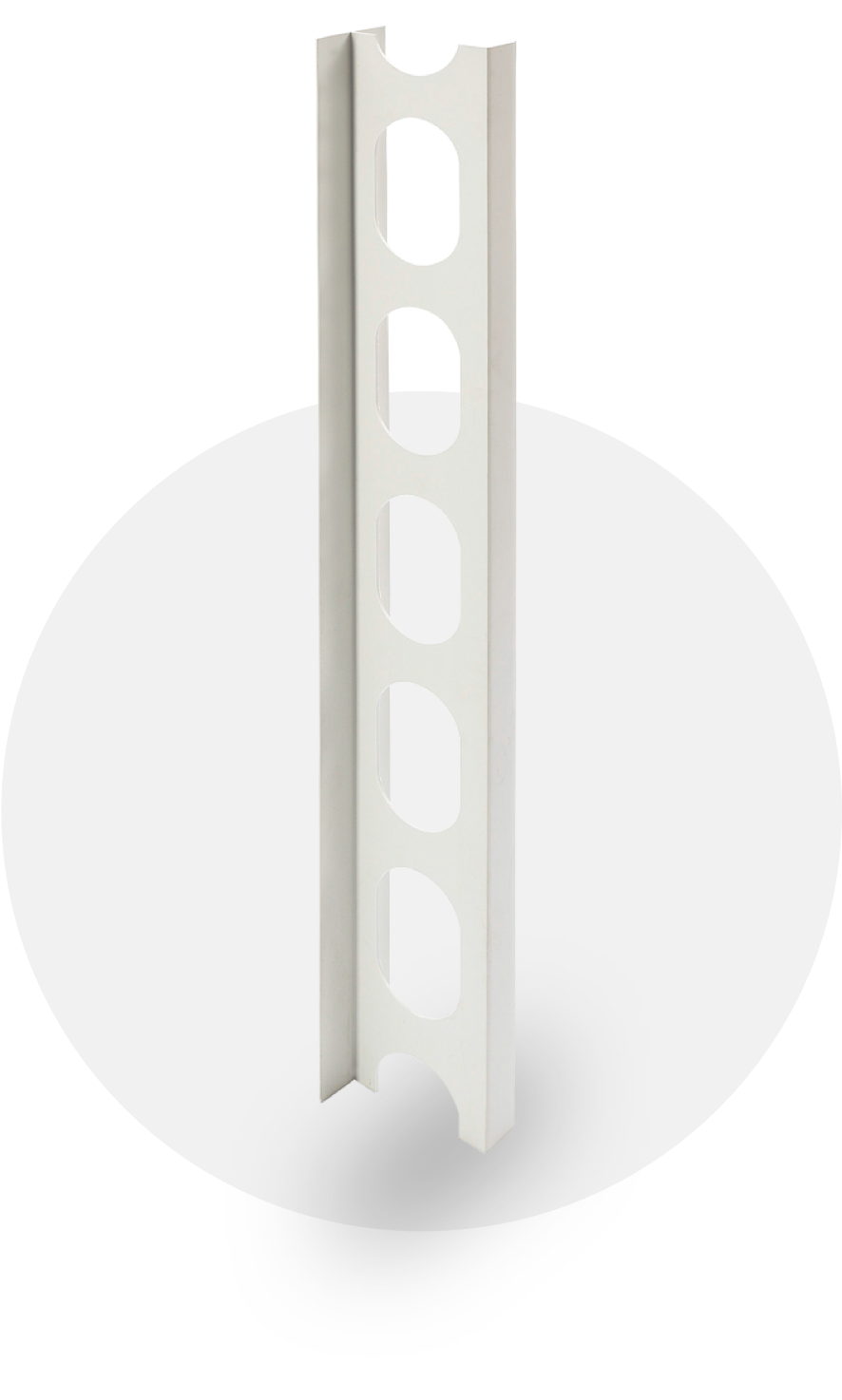

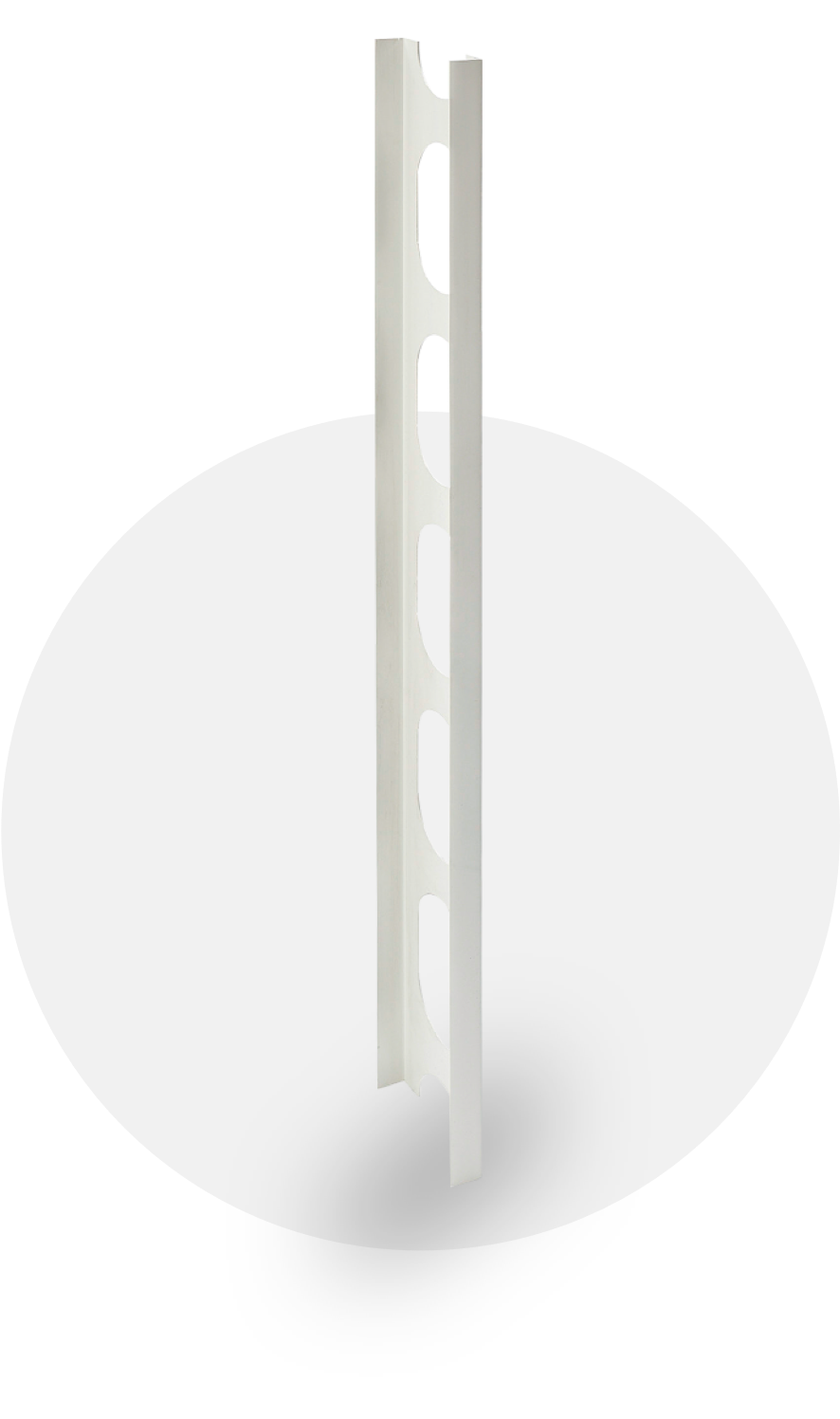

Rediwall Basement Wall Profiles

RW110

RW156

RW200

RW256

RW275

RW300

Wall Thickness

105mm

150mm

194mm

250mm

269mm

294mm

Acoustic Rating (STC)

50

54

58

60

61

61

Filled Wall Mass (kg/m2)

252

360

466

600

646

706

Fire Resistance Level (FRL)

Up to 90/90/90 (Load-bearing)

~120/120 (Non load-bearing)

240/240/240

240/240/240

240/240/240

240/240/240

240/240/240

Panel Type

Speedy Snap-In™ Panels

Speedy Snap-In™ Panels

Speedy Snap-In™ Panels

Slide-In Panels

Slide-In Panels

Slide-In Panels

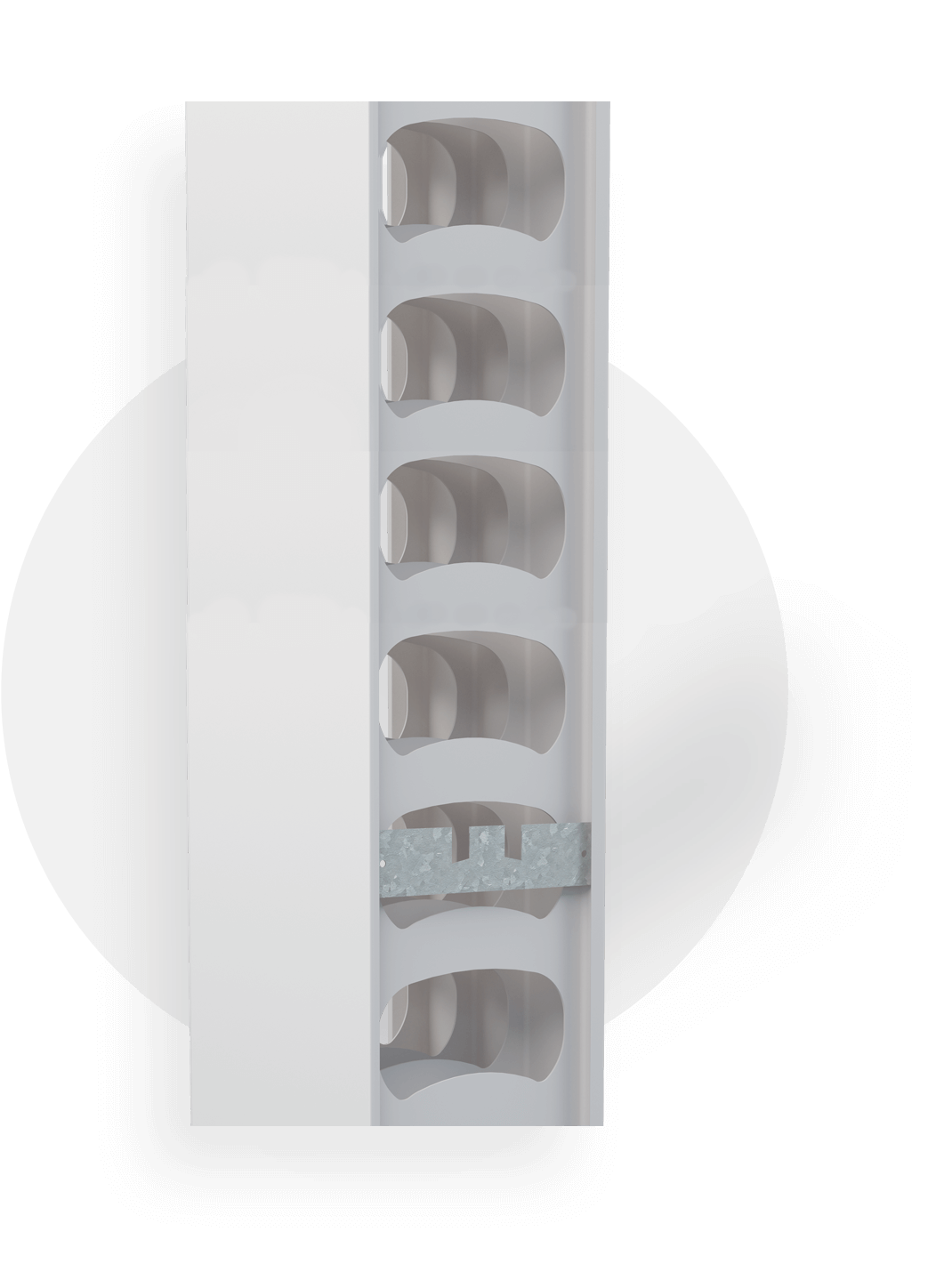

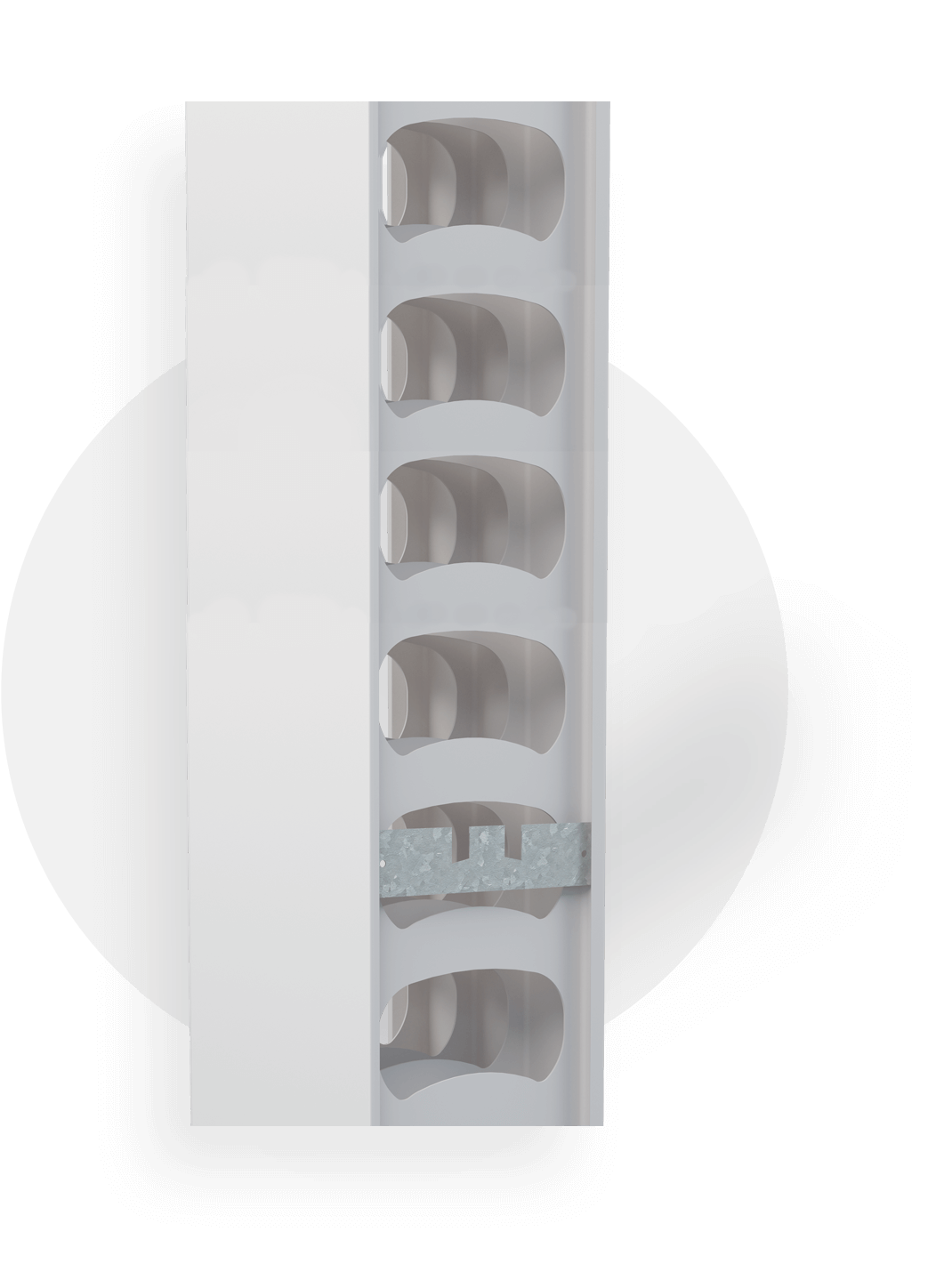

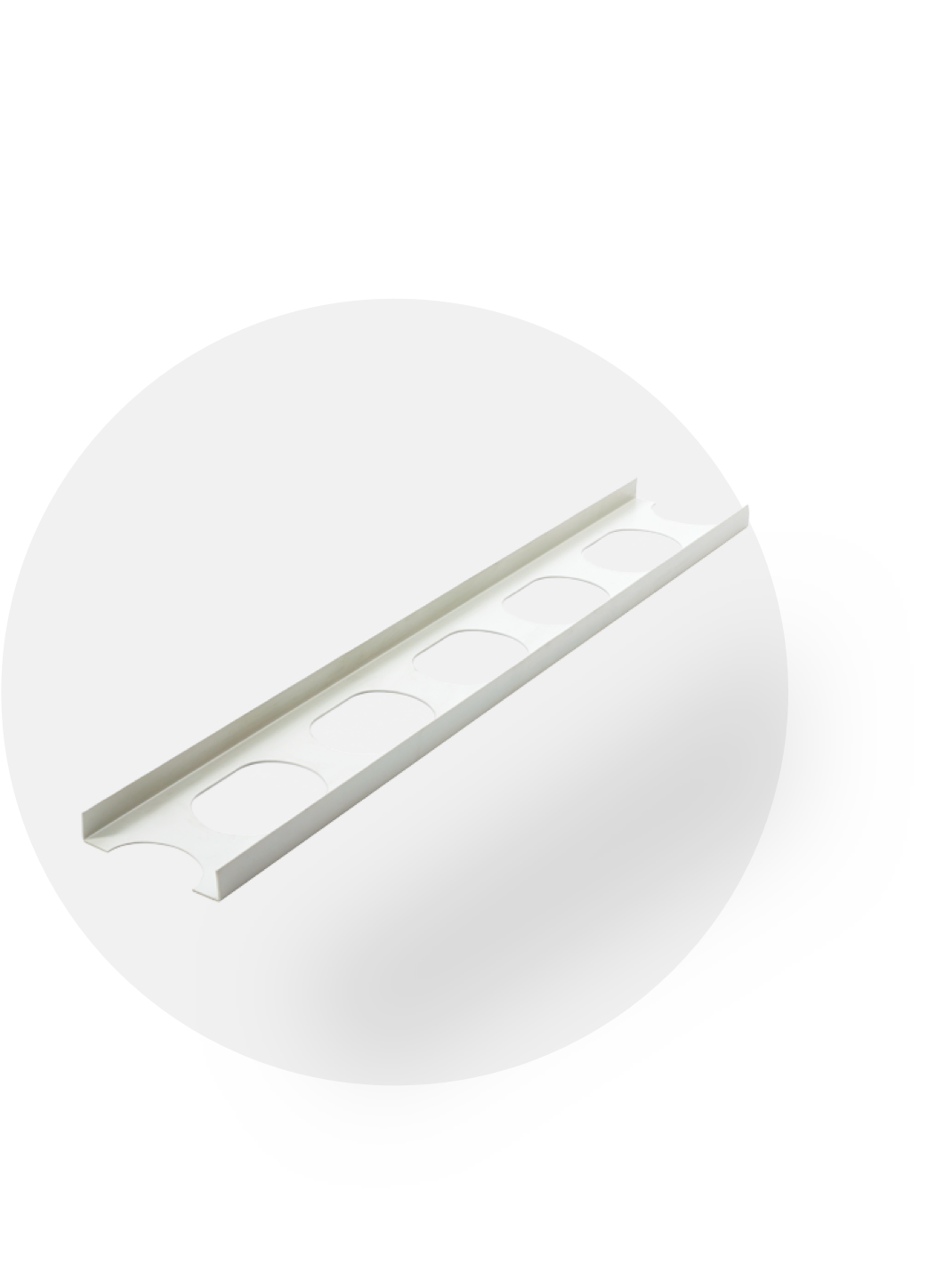

Rediwall Accessories

The afs rediwall® Vertical Bar Locator (VBL) allows for a more streamlined installation process, making the insertion of reinforcement bars quicker, easier and more efficient, with more accurate concrete coverage.

Rediwall Overview Video

What is Rediwall? Watch our overview video showing what Rediwall is and how to install it.

Rediwall vs. Blockwork Challenge Video

Watch a short video explaining the differences between AFS Rediwall and blockwork.

View Rediwall Resources

Access design guides, product brochures, compliance and certification documents, videos, and FAQs to get started using AFS Rediwall for your building projects.

Order AFS Rediwall

Ordering AFS Rediwall for your project is now even easier and quicker than before. To ensure you have ordered correctly, our team can double-check your quantities and lengths against a set of plans you are planning on using it for.

Design your Basement Walls in Rediwall today

Contact us today for a quote

Start Designing Your Basement Walls In Rediwall Today

Contact us today for a quote

FAQs

What is Rediwall?

AFS Rediwall is a PVC base permanent formwork system for concrete walls. Typically used for below ground and selected above ground applications.

What are the main applications for the Rediwall system?

- Basements

- Retaining walls

- Foundation walls

- Columns

- Retention tanks

- Intertenancy walls

- Corridor walls

- Lift and stair walls

What are your standard lead times for Rediwall basement walls?

We stock Rediwall panels in our warehouse in Nelson, and this can be delivered to you to anywhere in New Zealand when you need it onsite. If you require shop drawings, this process may be lengthened. Contact us directly for Rediwall availability.

What are the main benefits of Rediwall Basement Walls?

- Speed of construction

- Ease of installation and materials handling – lightweight

- High-quality semi-gloss, low-maintenance finish

- Water resistant

- Save on labour costs and time

How are Rediwall walls finished?

Rediwall offers a semi-gloss high quality low maintenance finish that typically requires no further finishing for below-ground applications. Contact us to discuss the level of finish required for your project.

Who installs the Rediwall?

Builders can install Rediwall themselves, although if you are unable to, we can provide a full supply and install service.

If you want to know the cost of our installation compared to just the supply, contact us directly.